Sensor Highlights

Installs on any machine within seconds through a Magnetic Connection.

Immediate Feedback through Visual fault-detecting indicators.

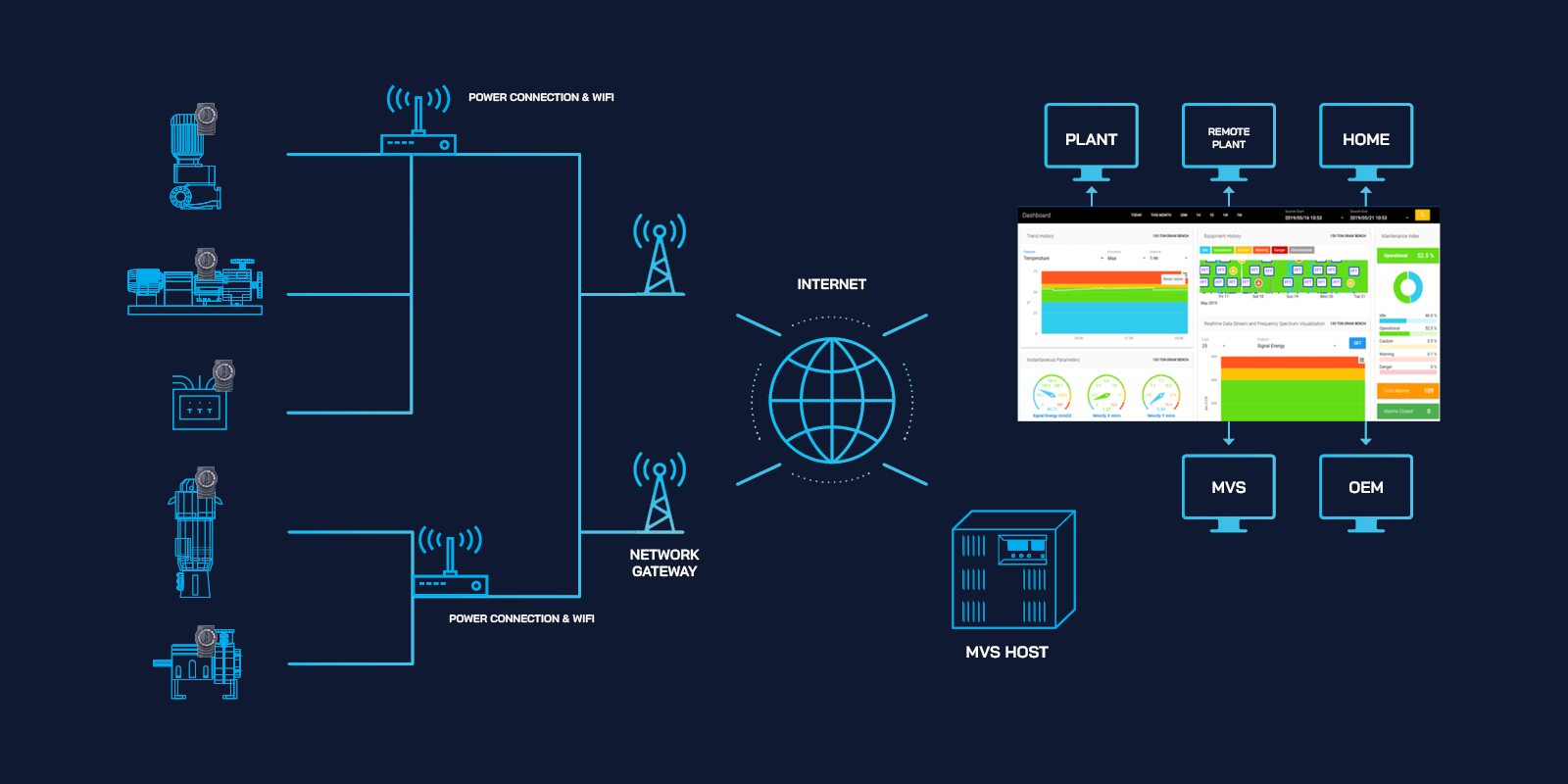

Monitor remotely and wirelessly, to mirror notifications and record data.

WHY MVS REALTIME 4.0?

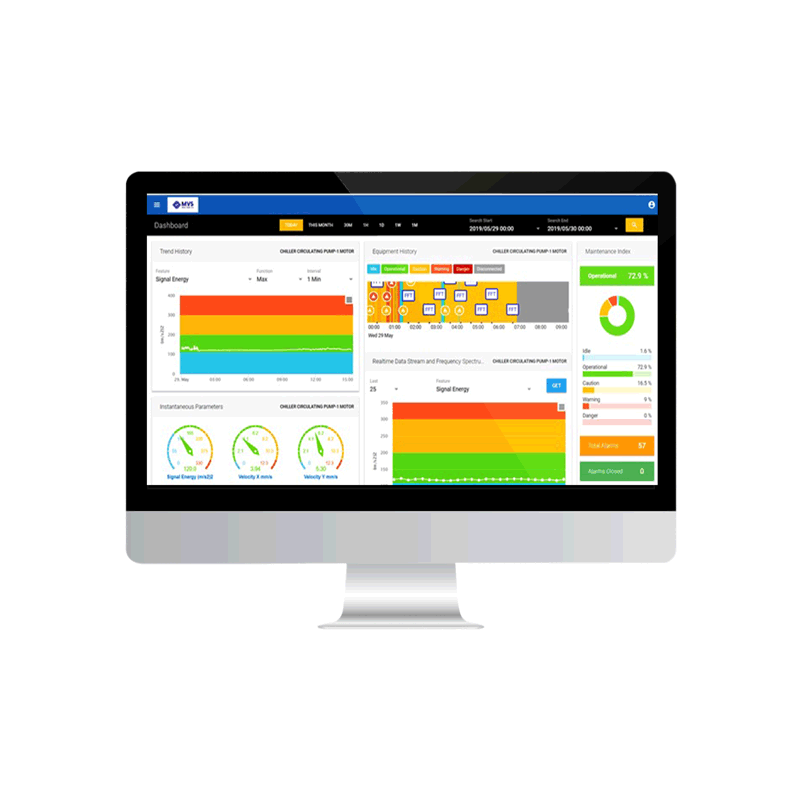

MVS RealTime 4.0 Accessibility

1. Mobile Android Application

2. Web-based Portal

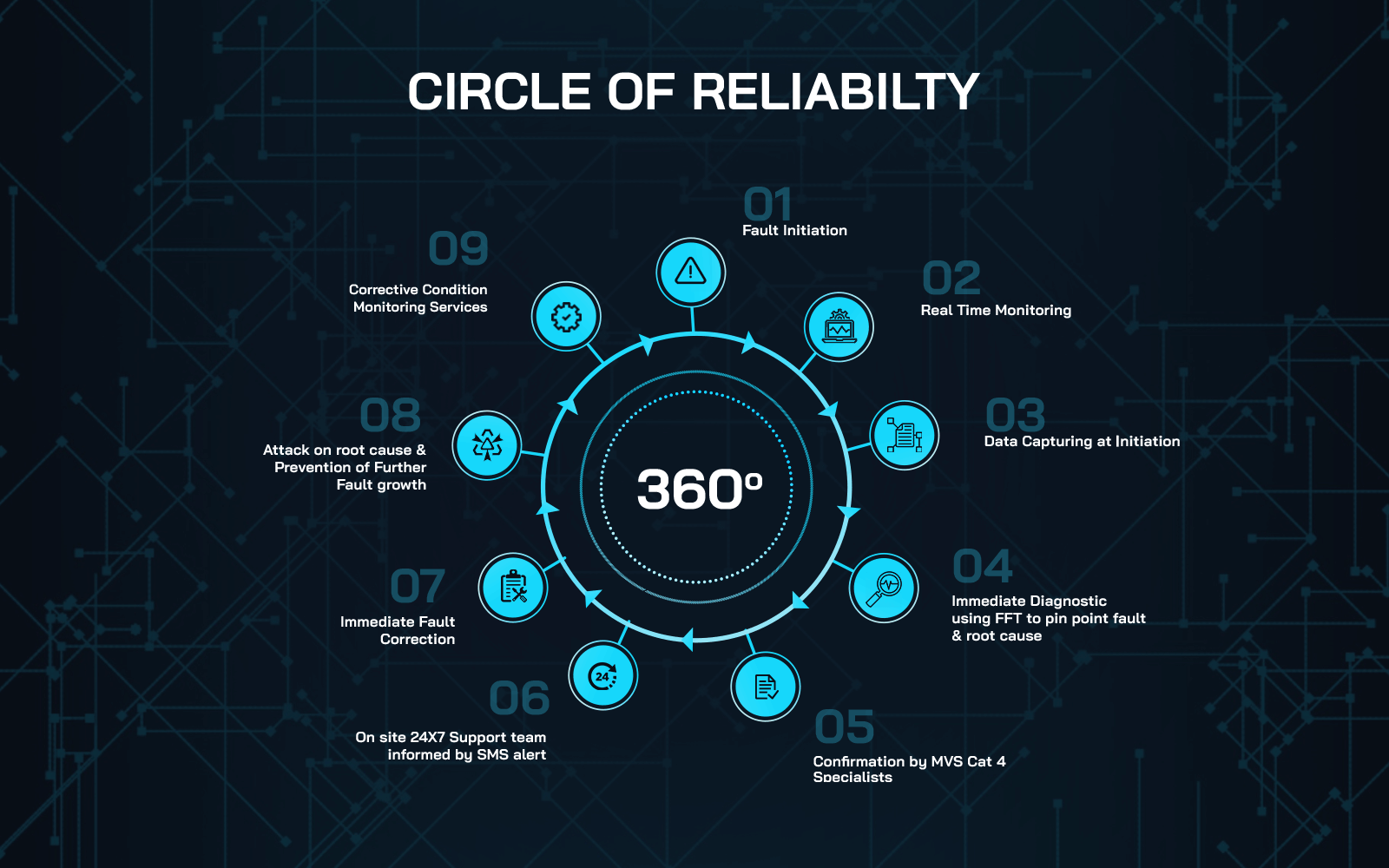

HOW IT WORKS

MVS RealTime 4.0 offers a flexible subscription-based reliability services to its customers by providing in-house smart sensor nodes along with Connectivity, Communication, Software Analytics which can be integrated on any IoT platform for dashboarding and reporting in order to provide a complete solution to its customers.

MVS RealTime 4.0 specializes in High-Frequency Data Analytics, such as Triaxial Vibration and Acoustic analyses,

Spectral analyses and Pattern recognition for data annotation and accurate predictions.

Machine's Data is collected and preserved every second and this can be viewed by you on our portal that

can be accessed anywhere at any time on your smart device. With this data in place, our highly experienced engineers help to detect faults at an early stage,

the root cause of the problems and ensure that right action is to be taken. We provide a wide range of condition

monitoring services for your machine to be healthy and happy!

Condition Monitoring Services

Vibration Analysis

Vibration Analysis is a predictive maintenance method which allows early problem detection in rotating machinery.

Insitu-Dynamic Balancing

"In Situ" technique uses influence coefficients matrix. The main advantage of balance is the cost savings.

Laser alignment

A modern Laser Shaft Alignment system utilizes laser-based technology to ensure that the shafts are coupled together along a perfect rotational centerline.

Thermography

Using Mechanical and Electrical thermography methods gives immediate results and minimizes failures of machines.

Oil analysis

Oil analysis is the laboratory analysis of a lubricant's properties, suspended contaminants, and wear debris.

NDT Services

Non destructive testing services encompass a wide range from visual inspection and LT to MP, UT, radiography, flaw detection, and eddy current to hardness testing.

Turbine Overhauls and maintenance

In order to maximize results a combination of repair facilities will enhance the quality of your capital parts package.

Remote Data Analysis

Ability to check the machinery health from remote work station.

Continuous Monitoring

Easy to install, permanent safe mounting and free software - the ACMEI On line system uses powerful electronics where space is extremely restricted.

Health Check

Machine profiling (information gathering), data base set up and conducting an initial (and ongoing) health check assessment on accessible plant items.

MCSA

This comprises of advanced non-destructive motor testing and analysis for both de-energized motor circuit analysis and energized electrical signature and power analysis.

Wind Turbine Condition Monitoring Services

Random wind speeds, changing load conditions on the generator, corrosive sea air, freezing conditions, resonance of blades, and misalignmnent can all affect the performance of wind turbines. We provide comprehensive services to ensure WTG reliability.

Industries We Serve

Steel and Metal

Glass & Refractory

Cement

Mining

Oil & Gas & Refinery

Chemical Processing

Pulp ,Paper & Priniting

Fabrics

Pharmaceutical

FMCG

Power & Utilities

Operation & Maintenance Services

Navy

Maritime