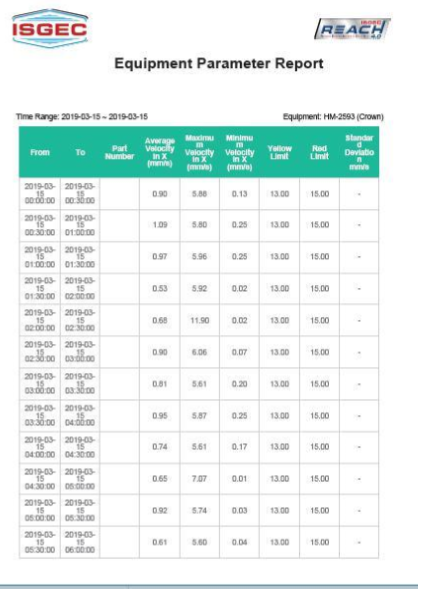

Objective

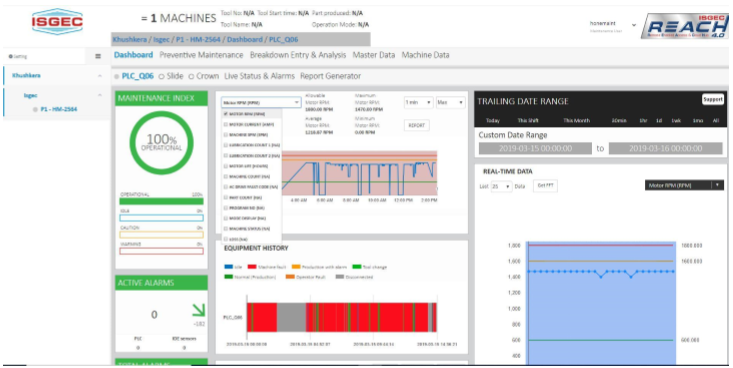

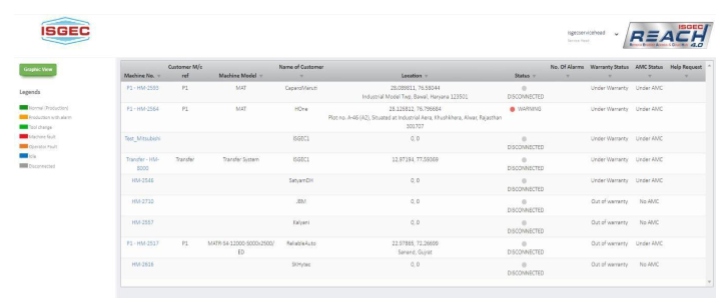

ISGEC wanted to transform their mechanical press and convert them into “SMART PRESS”, along with systematic monitoring of the health of the machine.

MVS REALTIME 4.0 IDE empowered IGSEC to offer good AMC and post-sales support to their clientele.