Introduction

A leading manufacturer and supplier of gears,

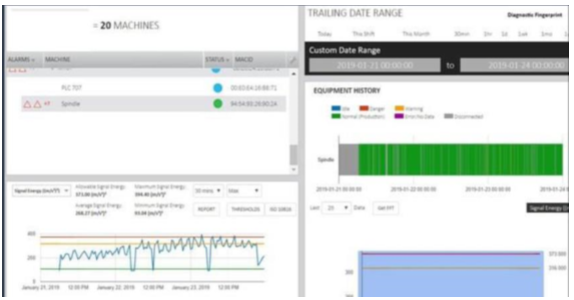

catering to all the leading manufacturers of commercial vehicles in India used

a horizontal machining centre (HMC)

which operated in three shifts, offered flexibility in operations and also fulfilled high volume machining needs